2011 HILLIARD'S 16 INCH BOTTOMER, 8 FOOT COLD PLATE, 16 INCH COATER. COOLING TUNNEL AND FEED TABLE NOT INCLUDED.

Model: HILLIARD'S 16 INCH BOTTOMER, 8 FOOT COLD PLATE, 16 INCH COATER. COOLING TUNNEL AND FEED TABLE NOT INCLUDED.

Year Built: 2011

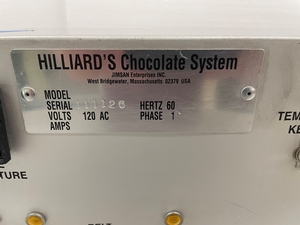

Serial Number: 111126

Condition: USED - FACTORY REFURBISHED

Features

Here's the economical answer to continuous production of a variety of superior quality chocolate candies.

Hilliard's Chocolate Coating Systems are precision designed for easy, profitable production of from 200 to 1500 pounds per day. Everything you need to coat chocolates of exceptional, consistent quality is included in a single unit. There is no need for separate melting or tempering units.

A Hilliard's Chocolate System will melt, temper, coat and cool your chocolate coatings quickly and efficiently, even with inexperienced operators. Simplicity of operations assures top quality control throughout the processing operation.

Easy Chocolate Coating System Features:

Tempering Bottomer - This permits the use of real chocolate rather than compound coating in the bottomer. Use of the same type of coating in the bottomer and the coater eliminates any incompatibility issues.

Coater - The coater assures a continuous supply of properly tempered chocolate. The dry air heating means no water needs to be in proximity to the chocolate. The tempering kettle chocolate is held precisely within 1 degree Fahrenheit of the selected temperature. Auxiliary heaters maintain chocolate temperature in the curtain hopper and wire belt. The variable speed shaker controls coating thickness on the center. A detailer rod removes "tails" from the coated piece as it transfers to the cooling belt. A double curtain with independent adjustments assures complete coating for all size and shaped pieces.

Optional Cooling Tunnel - the cooling tunnel provides thorough cooling of all pieces. Coated centers will be cooled in as little as 5 to 7 minutes. The "stringing" area of the tunnel belt is used to decorate coated centers by hand or machine before the product enters the tunnel. The packaged area at the exit end of the tunnel allows packing of the coated and cooled items. Precise control of the cooling temperature and humidity assures chocolates with a high luster.

Optional Feed Belt - Allows automatic loading from extruders or by continuous hand feeding.

Electrical Requirements: Three 20 amp circuits, each 120 volts, 60 cycles. No water or air connection required.

Description

Factory refurbished 16" Tempering Bottomer, 8' Cold Plate, and 16" Coater. Runs left to right. Cooling Tunnel and Feed Table NOT included.

ADD A NEW COOLING TUNNEL TO THIS REFURBISHED UNIT. OPTIONS INCLUDE:

New - 16" x 10' Cooling Tunnel - $40,900 for a total price of $80,900 (Overall length = 26 feet) OR

New - 16" x 15' Cooling Tunnel - $48,900 for a total price of $88,900 (Overall length = 31 feet) OR

New - 16" x 20' Cooling Tunnel - $56,900 for a total price of $96,900 (Overall length = 36 feet).

All tunnel versions include 2 foot stringing and 2 foot packing areas.

Belt Speed Variable 0-2 feet per minute

ADD A 4 FOOT FEED TABLE FOR $7,900.

Packing and Shipping Charges extra.

Price includes installation and training.

Call to order or check lead times.

$40,000.00